We Setup

Wood Seasoning Plant

for Maximum Strength & Efficiency

Industry-leading kiln drying technology for faster, cost-effective, and high-quality wood processing.

30+ Years

Experience

ISO Certified

for Quality & Experts

Eco-Friendly

Technology

Why Choose Tripti WSP Technology?

Industry-leading features that deliver superior results and maximize your return on investment.

Fully Automatic Operation

Runs without human support; no operator needed. The system works 24/7 with smart controls for smooth, hassle-free wood seasoning.

Zero Pollution Drying

No wood burning or smoke generation. Our technology ensures clean, eco-friendly seasoning with safe, pollution-free operation every time.

Low Power Consumption

Uses minimal electricity with efficient heating. Designed to reduce energy bills while delivering consistent, uniform drying performance.

Natural-Like Seasoning Quality

Replicates natural drying conditions with controlled airflow and temperature for superior, stable, crack-free wood seasoning results.

30+ Years of Expertise in Dehumidifier-Based Kiln Drying

1993

Tripti Wood Seasoning Plant has been at the forefront of wood processing technology in India for over three decades. Our innovative dehumidifier-based kiln drying solutions have transformed the industry, providing manufacturers with faster, more efficient, and environmentally responsible wood seasoning.

- Over 30 years of expertise in dehumidifier-based kiln drying

- Trusted by leading wood manufacturers across India

- ISO certified quality management systems

- Continuous innovation in eco-friendly technology

Trusted Since

1993

500+

Projects Completed

200+

Happy Clients

99%

Success Rate

Our Technology

Innovation Meets Sustainability

Our dehumidifier-based kiln drying technology represents the perfect balance of efficiency, quality, and environmental responsibility.

Sustainable Process

Eco-friendly dehumidification reduces environmental impact

Energy Savings

Up to 40% reduction in operational costs

Superior Quality

Maintains wood integrity and natural characteristics

Automated Control

Smart monitoring and adjustment systems

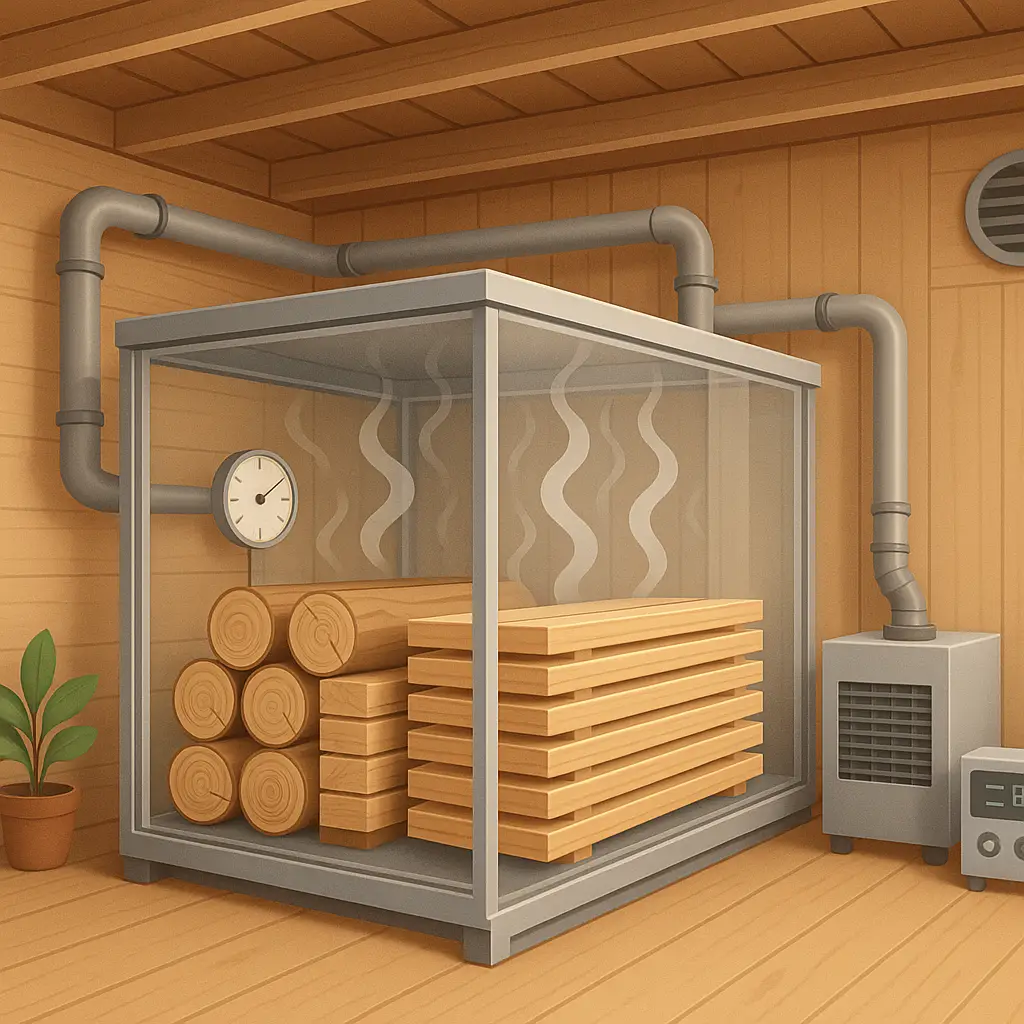

How it Works

Our dehumidifier-based system removes moisture from wood through controlled temperature and humidity cycles, ensuring uniform drying without the stress and damage associated with conventional methods.

Load & Configure

Wood is loaded and moisture targets are set

Controlled Drying

Dehumidifiers extract moisture gradually

Quality Output

Perfect moisture content achieved

Our Projects

Recent Installations

RL Khanna Mr Joseph

Noida, Uttar Pradesh

View Details ≫

Mr Bheesham Sethi

Ambala , Haryana

View Details ≫

Lakshminarayan Ply and Doors

Mr Narendra/Dharmendra

Bangalore

View Details ≫

FAQ’S

Wood seasoning is the process of drying wood to remove moisture content, preventing warping, cracking, and fungal growth, thus improving durability and usability.

The ideal moisture content depends on the application but generally ranges between 6-12% for furniture and construction purposes.

Kiln drying is faster, more controlled, and ensures uniform moisture levels compared to air drying, which can take months and be less consistent.

It removes moisture using controlled heat and dehumidification technology, ensuring even drying without excessive energy consumption.

Yes, kiln-dried wood is more stable, durable, and resistant to insects, making it a superior choice for various industries.

What Our Clients Say

Mr Bheesham Sethi

Exceptional service and top-notch technology. The quality of Tripti Wood Seasoning Plants is unmatched!”

Mr Joseph

“The best investment we made for our woodworking business. Highly efficient and reliable!

Mr Sirjudin Shah

“Their kiln drying chambers have transformed our production. Wood quality has improved, and energy costs are significantly lower!”

Recent Installations

How Wood Moisture Affects Furniture Quality (Expert Guide)

How to Setup Wood Seasoning Plant

Why Modern Wood Industries Are Shifting to Automatic Seasoning Plants

Ready to Transform Your Wood Processing?

Get a customized quote for your wood seasoning needs. Our experts are ready to help you choose the perfect solution for your business.