Wood Seasoning Plant for Construction & Infrastructure

Stop Wood Defects, Boost Construction Quality

Why 500+ Construction Firms Choose Tripti Wood Seasoning Plants

Each benefit = Specific outcome + Social proof

Eliminate 85% of Structural Defects

What You Get:

- Zero warping in load-bearing beams

- No splitting in joists and rafters

- Dimensionally stable timber for precision construction

Get Timber Ready 25X Faster

What You Get:

- 7–14 days vs. 6–12 months air drying

- Meet aggressive project deadlines

- No weather dependency

Cut Material Waste by 65-80%

What You Get:

- ₹8–15 lakhs saved per 100 cu.m processed

- Predictable material costs

- Higher profit margins

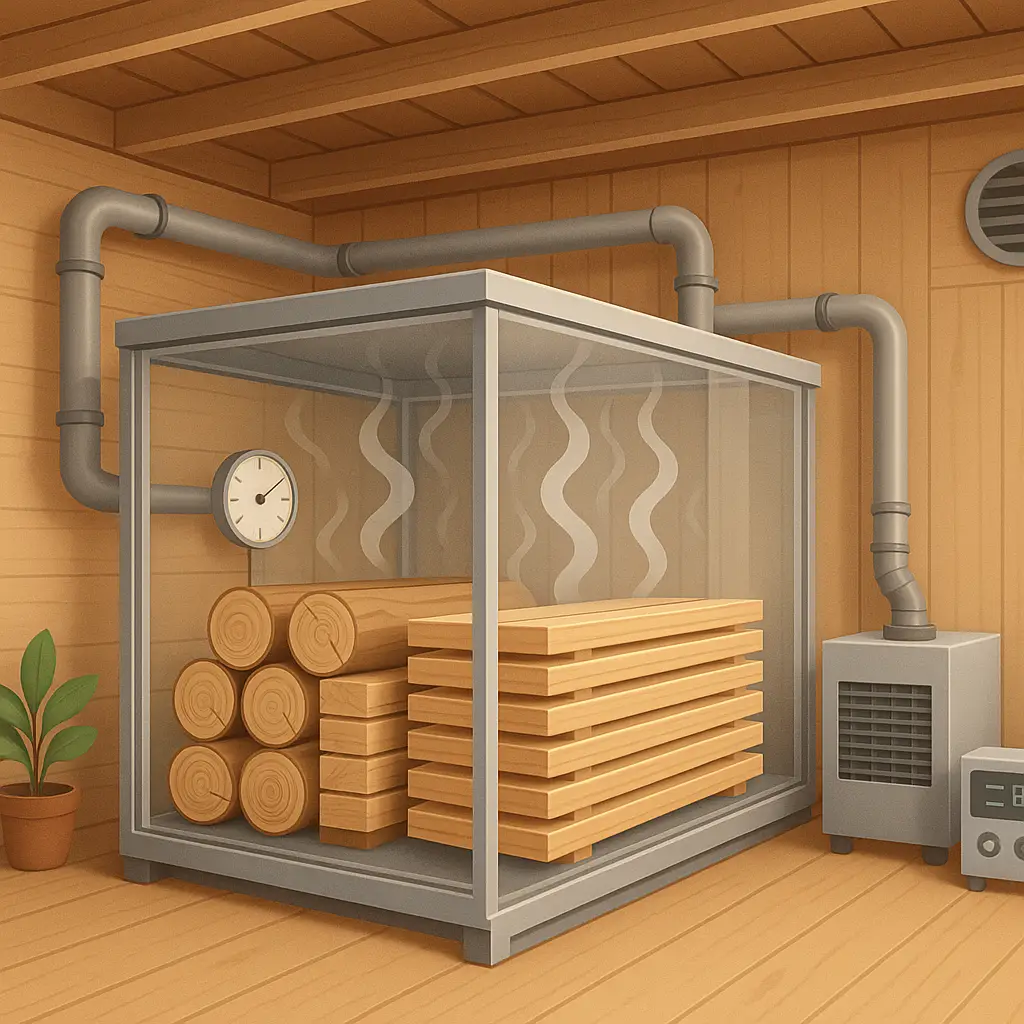

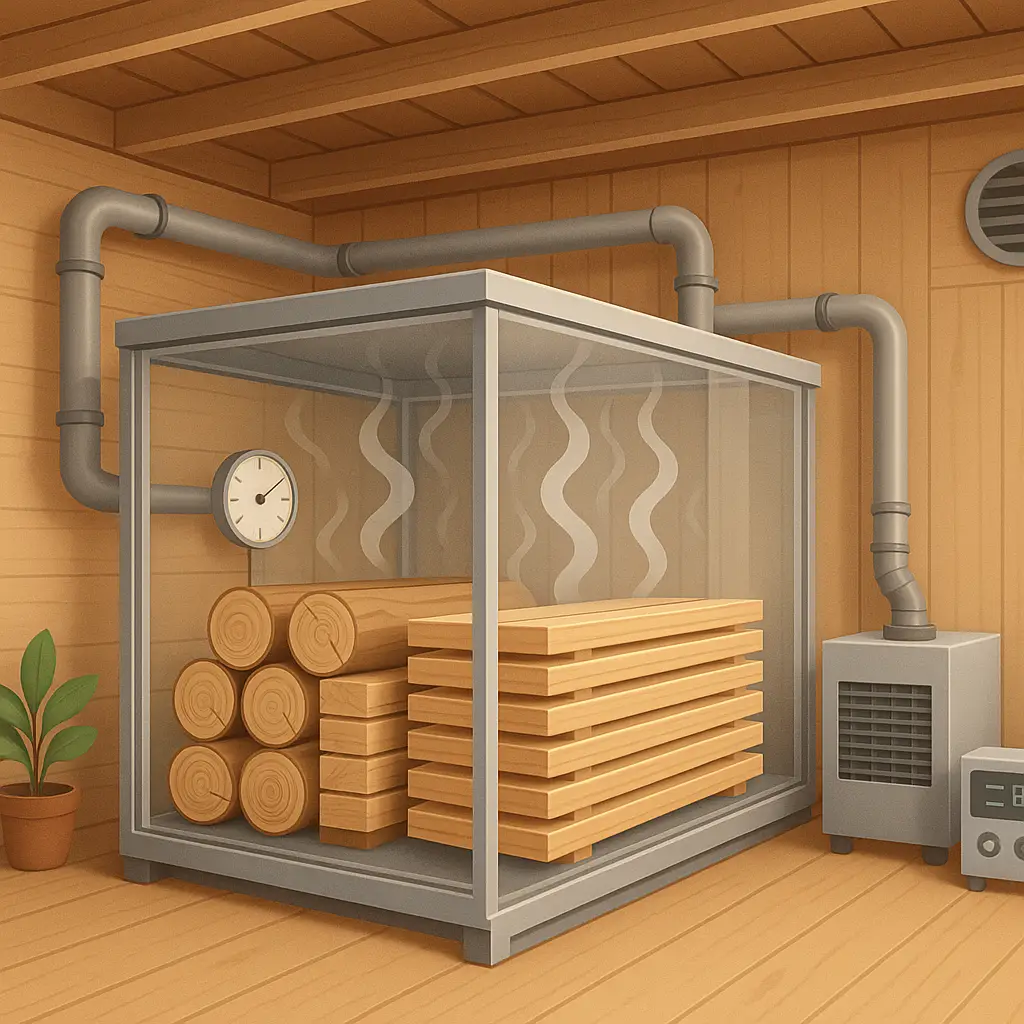

Advanced Kiln Technology That Guarantees Results

Reduce technical jargon, focus on outcomes

Dehumidifier-Based System

Dehumidification-Based System: Saves 40% electricity, preserves timber strength, and ensures zero emissions, with closed-loop heat recovery, PLC moisture control, and low energy use of 0.8–1.2 kWh per kg water removed.

Board Automation System

Automated system reduces labor costs by 60% and enables 24/7 unmanned operation. Real-time monitoring through a mobile app ensures full control and efficiency. Visual: GIF showing automated loading and unloading for smooth, continuous workflow.

Energy-Efficient Design

Save ₹3–7 lakhs yearly on electricity with faster 12–18 month payback and sustainable operations. A proof chart compares monthly operating costs, showing clear efficiency advantages and long-term savings making the system a smart overall investment.

Find Your Perfect Wood Seasoning Plant

Customizable Solutions Based on Your Needs

Interactive Selector:

-

Step 1: What's your monthly timber processing volume?

- 50-200 cu.m (Small contractors)

- 200-800 cu.m (Regional builders)

- 800-3000 cu.m (Large infrastructure)

- 3000+ cu.m (Industrial suppliers)

-

Step 2:Primary application?

- Structural beams & joists

- Bridge & marine timber

- Decking & outdoor structures

- Multi-purpose construction

-

Step 3:Current drying method?

- Air drying (natural)

- Existing conventional kiln

- No existing facility

Real Numbers from Real Construction Projects

| Metric | Before Tripti | After Tripti | Savings |

|---|---|---|---|

| Material Rejection Rate | 18-25% | 2-4% | ₹18L/year |

| Seasoning Time | 180-240 days | 7-14 days | 45 days faster |

| Moisture Variation | ±8-12% | ±1% | Zero rework |

| Energy Cost per cu.m | ₹1,200 | ₹480 | 60% reduction |

| Labor Hours | 240 hrs/month | 85 hrs/month | ₹3.5L/year |

Construction Industry Benefits (Outcome-Focused)

-

75-85% Reduction in Site Rejections

Mean fewer delays, penalties, and material reorders -

40-60% Faster Project Completion

Meet tight deadlines and secure early completion bonuses -

Grade-A Structural Compliance

Pass inspections first time, every time -

Predictable Material Costs

No surprise expenses from damaged timber

FAQ’S

Fast deployment:

- Site preparation: 7-10 days

- Equipment installation: 10-15 days

- Testing & commissioning: 3-5 days

- Total: 3-4 weeks from order confirmation

We handle everything including civil work, electrical setup, and initial batch supervision.

Complete Quality Assurance Process

Four-Stage Quality Protocol

- Wood Analysis : Detailed species identification and moisture content measurement

- Chamber Treatment : Controlled dehumidification with precise temperature regulation

- Quality Testing : Rigorous moisture verification and structural integrity checks

- Final Inspection : Complete documentation and certification for quality records