Wood Seasoning Plant for Furniture Manufacturers

Stop Wood Defects, Boost Production Quality

Why Furniture Manufacturers Choose Our Wood Seasoning Plants

Precision Moisture Control for Flawless Furniture

Zero Defects

Eliminate warping, cracking, and splitting with uniform heat distribution

Faster Production

Reduce seasoning time by 50% compared to air drying

Cost Savings

Cut material waste by 80-90% and energy costs by 40%

Consistent Quality

Automated controls deliver perfect results batch after batch

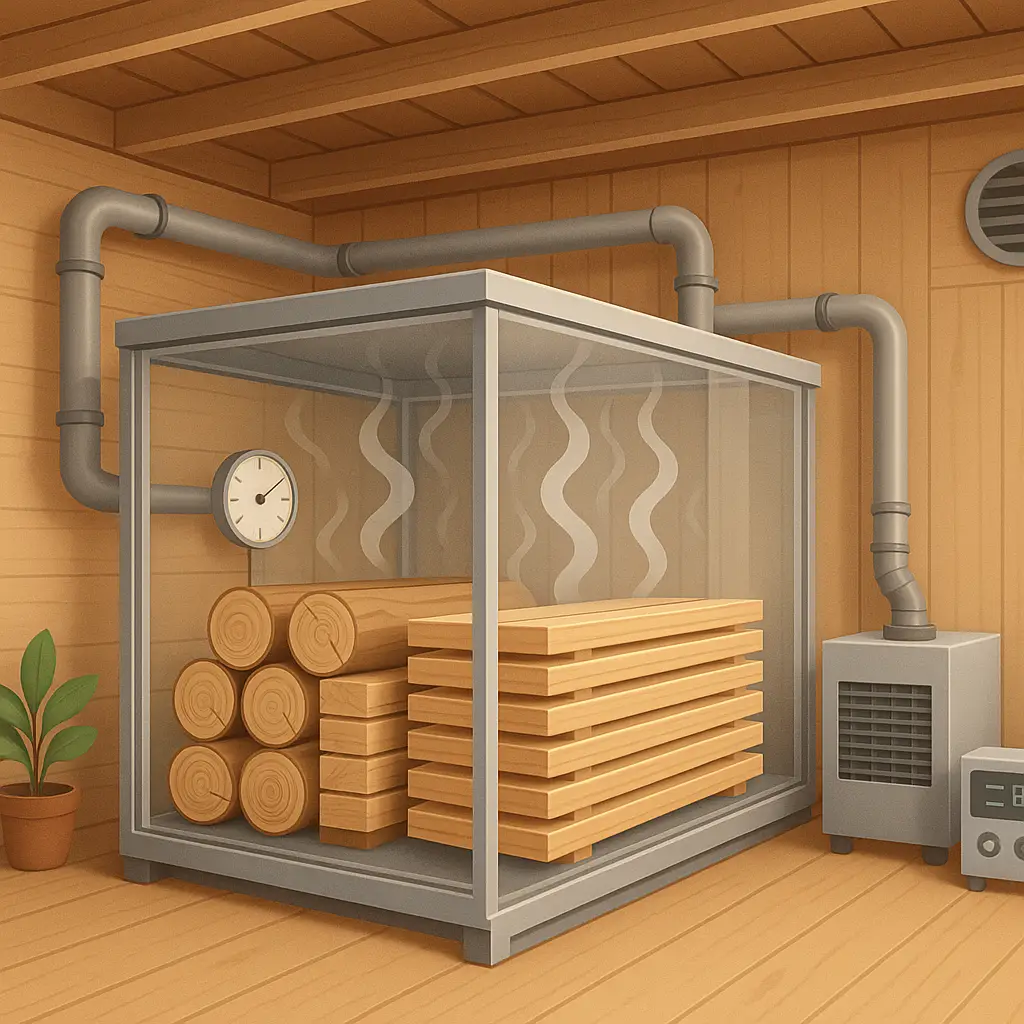

Advanced Kiln Drying Technology

Dehumidifier-Based System

Our advanced dehumidification technology maintains precise temperature and humidity levels throughout the drying process, ensuring optimal results for hardwoods, softwoods, and exotic species.

Smart Automation

Real-time moisture monitoring, programmable drying schedules, and automatic temperature adjustments work together to ensure efficient, controlled, and consistent wood drying.

Energy-Efficient Design

Heat recovery systems and insulated chambers reduce operational costs by 40%, delivering significant savings on every drying cycle.

Customizable Solutions for Every Production Need

Flexible Chamber Configurations

Small Scale

50-100 cubic feet for specialty workshops and custom furniture makers

Medium Scale

200-500 cubic feet for growing furniture manufacturers

Large Scale

1000+ cubic feet for high-volume production facilities

Custom Sizing

Tailored configurations for unique requirements

Proven ROI for Furniture Manufacturing

- Material Savings : Reduce defect-related waste by 80-90%

- Production Speed Season wood in 3-7 days vs. 6-12 months air drying

- Energy Efficiency 40% lower operational costs than conventional kilns

- Quality Improvement 90% reduction in customer complaints and returns

- Typical ROI 18-24 months payback period

Furniture manufacturers implementing our systems experience:

- 25-35% reduction in raw material costs annually

- 50-60% faster time-to-market on orders

- Improved product durability and customer satisfaction

- Enhanced reputation for quality craftsmanship

FAQ’S

Consistent 6-12% moisture content with ±1% precision, ideal for furniture manufacturing.

Yes, 40-60% more efficient than conventional steam kilns with heat recovery technology.

Minimal. Quarterly filter cleaning and annual system checks. Full maintenance support included.

Complete Quality Assurance Process

Four-Stage Quality Protocol

- Wood Analysis : Detailed species identification and moisture content measurement

- Chamber Treatment : Controlled dehumidification with precise temperature regulation

- Quality Testing : Rigorous moisture verification and structural integrity checks

- Final Inspection : Complete documentation and certification for quality records

Ready to Transform Your Wood Processing?

Get a customized quote for your wood seasoning needs. Our experts are ready to help you choose the perfect solution for your business.