Wood Seasoning Plant for Sawmills & Lumber Yards

Increase Lumber Value by 45% & Reduce Drying Time from Months to Days

Why 500+ Sawmills & Lumber Yards Choose Tripti Wood Seasoning Plants

Sell at 45-60% Higher Prices

- Air-dried: ₹20-25K/cu.m

- Kiln-dried: ₹35-45K/cu.m

- Access furniture & export markets

- Become premium supplier in region

“Average selling price jumped from ₹22,000 to ₹38,000 per cu.m”

Turn Inventory 8X Faster

- 7-14 days vs. 6-12 months drying

- Sell same lumber 8-10 times/year

- Unlock massive working capital

- Accept custom orders with confidence

“Same capital rotates 8 times = ₹8-12L additional annual profit”

Cut Lumber Waste by 70%

- Reduce defects from 25% to 3-5%

- ₹12-18 lakhs saved per 500 cu.m

- Sell nearly everything you cut

- Higher grade yields = better margins

“Rejection rate dropped from 28% to 4%—₹15L saved annually”

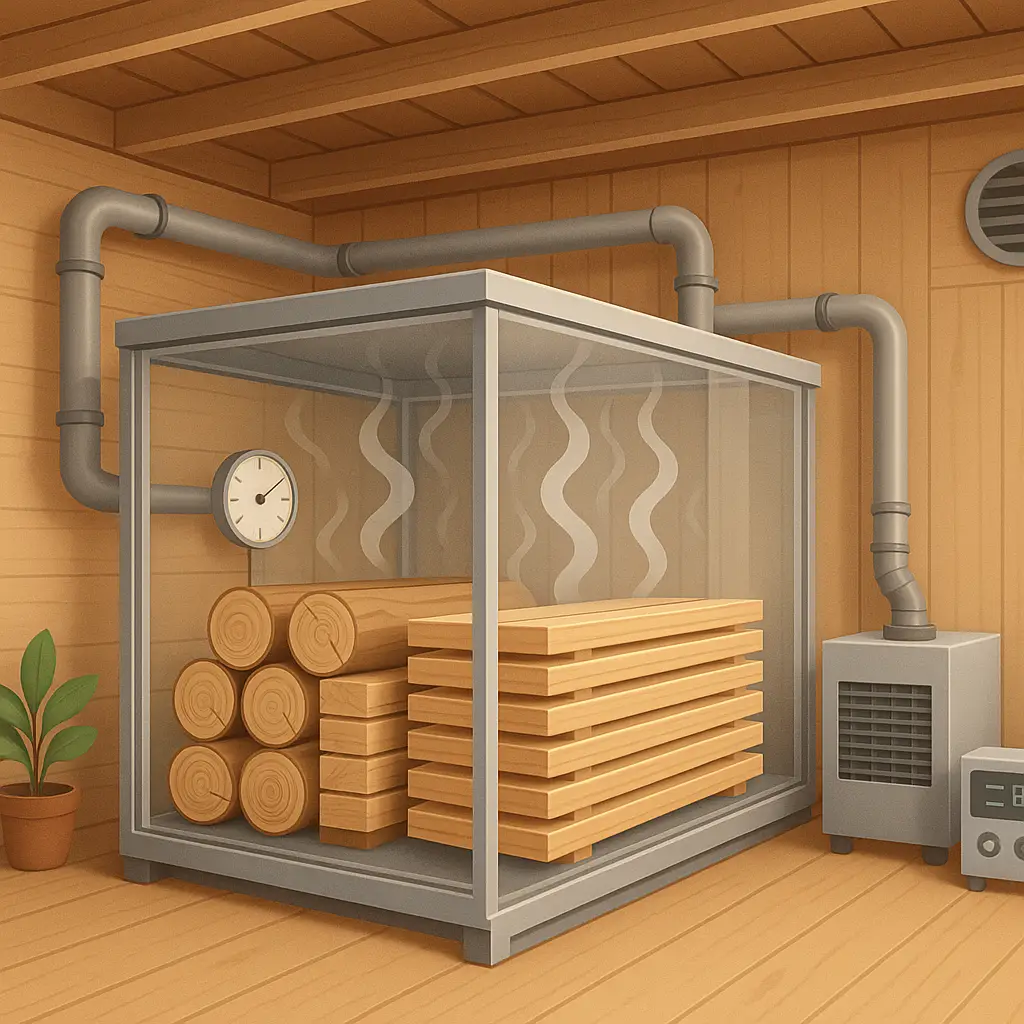

Advanced Kiln Technology That Guarantees Results

Dehumidifier-Based System

What It Means for Sawmills: Saves 40% electricity compared to steam kilns, processes mixed species in same batch, and requires no boiler. Features closed-loop heat recovery, PLC moisture control, and uses only 0.8-1.2 kWh per kg water removed.

Board Automation System

What It Means for Lumber Yards: Automated system reduces labor costs by 60% and enables 24/7 unmanned operation with load-and-forget convenience. Real-time batch tracking through mobile app.

Energy-Efficient Design

What It Means for Profits: Save ₹5-9 lakhs yearly on electricity with drying cost of only ₹450-600 per cu.m. Quick 12-16 month payback with eco-friendly operations.

Find Your Perfect Wood Seasoning Plant

Customizable Solutions Based on Your Sawmill Volume

Interactive Selector:

-

Step 1: What's your monthly lumber cutting volume?

- 50-150 cu.m (Small sawmill)

- 150-500 cu.m (Medium sawmill)

- 500-2000 cu.m (Large sawmill/lumber yard)

- 2000+ cu.m (Industrial timber operation)

-

Step 2: What type of wood do you mainly process?

- Softwood (Pine, Deodar, Fir)

- Hardwood (Teak, Sal, Sheesham)

- Mixed species

-

Step 3: Target market?

- Local construction/builders

- Furniture manufacturers

- Flooring companies

- Export markets

-

Step 4: Current drying method?

- Air drying in yard

- No drying (sell green)

- Existing old kiln

- Outsource to others

Real Numbers from Real Sawmills & Lumber Yards

| Business Metric | Before Tripti | After Tripti | Your Gain |

|---|---|---|---|

| Lumber Selling Price | ₹20-25K/cu.m | ₹35-42K/cu.m | +75% revenue |

| Inventory Turnover | 240 days | 12-14 days | 17X faster |

| Wood Waste/Defects | 22-30% | 3-5% | ₹12-18L/year |

| Premium Buyers | 0-2 clients | 15-25 clients | New markets |

| Working Capital Blocked | ₹45-80L | ₹5-8L | Unlocked cash |

| Staff (drying dept) | 6-8 people | 2-3 people | ₹4-6L/year |

Sawmill & Lumber Yard Benefits

- 45-60% Higher Lumber Prices Kiln-dried premium commands top market rates. Supply furniture makers, exporters, architects.

- 8-10X Faster Inventory Turnover Same lumber sold 8 times per year instead of once. Unlock working capital and accept custom orders.

- 70% Less Material Waste Reduce cracking from 25% to 3-5%. Nearly everything you cut becomes sellable premium lumber.

- Access Premium Markets Supply furniture manufacturers, flooring companies, exporters, and high-end construction projects.

- Predictable Delivery Timelines Accept custom orders with confidence. No weather dependency or seasonal delays.

FAQ’S

Fast deployment:

- Site preparation: 7-10 days

- Equipment installation: 10-15 days

- Testing & commissioning: 3-5 days

- Total: 3-4 weeks from order confirmation

We handle everything including civil work, electrical setup, and initial batch supervision.

Complete Quality Assurance Process

Four-Stage Quality Protocol

- Wood Analysis : Detailed species identification and moisture content measurement

- Chamber Treatment : Controlled dehumidification with precise temperature regulation

- Quality Testing : Rigorous moisture verification and structural integrity checks

- Final Inspection : Complete documentation and certification for quality records